What Size Drill Bit Do I Need for a 10-32 Tap? The Definitive Guide

Are you staring down the barrel of a threading project, wondering, “What size drill bit do I need for a 10-32 tap?” You’re not alone. Choosing the right drill bit is crucial for creating strong, accurate threads, preventing broken taps, and ultimately, ensuring the success of your project. This comprehensive guide will walk you through everything you need to know, from the basic calculations to advanced techniques, ensuring you get perfect threads every time. We’ll delve into the specifics of 10-32 taps, explore the underlying principles, and offer practical tips based on years of experience. This isn’t just a simple chart; it’s a deep dive into the art and science of threading.

Understanding the 10-32 Tap: A Deep Dive

Before we pinpoint the ideal drill bit size, let’s understand what a 10-32 tap actually is. The “10” refers to the nominal size of the screw, which is approximately 0.190 inches in diameter. The “32” indicates the number of threads per inch (TPI). This combination determines the overall strength and holding power of the threaded connection. Understanding these specifications is key to selecting the correct drill bit and achieving a secure, reliable thread.

Think of the screw thread as a helical ramp. The ’10’ dictates the overall diameter of the screw, determining how much material it displaces as it’s inserted. The ’32’ dictates the steepness of the ramp. A higher TPI means more threads per inch, leading to a finer, shallower thread, which can be advantageous in certain applications requiring precise adjustments or resistance to vibration.

The Importance of Thread Engagement

Thread engagement refers to the percentage of the screw thread that is actually engaged with the tapped hole. Ideally, you want around 75% thread engagement for optimal strength. Less than that, and the connection becomes weaker. More than that, and you risk damaging the tap or stripping the threads. This is where the drill bit size becomes critical – it directly influences thread engagement.

Materials Matter: Impact on Drill Bit Selection

The material you’re tapping into plays a significant role. Softer materials like aluminum or plastic are more forgiving, while harder materials like steel or stainless steel require more precision and potentially a different drilling technique. When working with harder materials, using cutting fluid and maintaining a slow, steady drilling speed becomes even more crucial.

The Magic Number: What Size Drill Bit for a 10-32 Tap?

The standard drill bit size for a 10-32 tap is a #21 drill bit, which has a diameter of 0.159 inches. However, this is just a starting point. Several factors can influence the ideal drill bit size, including the material being tapped, the desired thread engagement, and the specific tap being used. Consulting a tap drill chart is always a good practice.

Calculating the Tap Drill Size: The Formula

For those who prefer a more precise approach, you can calculate the tap drill size using the following formula:

Tap Drill Size = Nominal Tap Size – (1 / Threads Per Inch)

For a 10-32 tap:

Tap Drill Size = 0.190 – (1 / 32) = 0.190 – 0.03125 = 0.15875 inches

This calculation confirms that a #21 drill bit (0.159 inches) is indeed the correct size. However, it’s always wise to double-check your calculations and consider the material you’re working with.

Tap Drill Charts: Your Go-To Resource

Tap drill charts are invaluable resources that provide recommended drill bit sizes for various taps. These charts are readily available online and in most machine shops. They often include information about different materials and thread engagement percentages.

Choosing the Right Drill Bit: Factors to Consider

Selecting the perfect drill bit involves more than just knowing the size. You also need to consider the material, type of drill bit, and drilling technique.

Drill Bit Material: High-Speed Steel (HSS) vs. Cobalt

High-speed steel (HSS) drill bits are a good general-purpose option suitable for most materials. However, for harder materials like stainless steel or hardened steel, cobalt drill bits are a better choice. Cobalt drill bits are more resistant to heat and wear, allowing for faster drilling speeds and longer tool life.

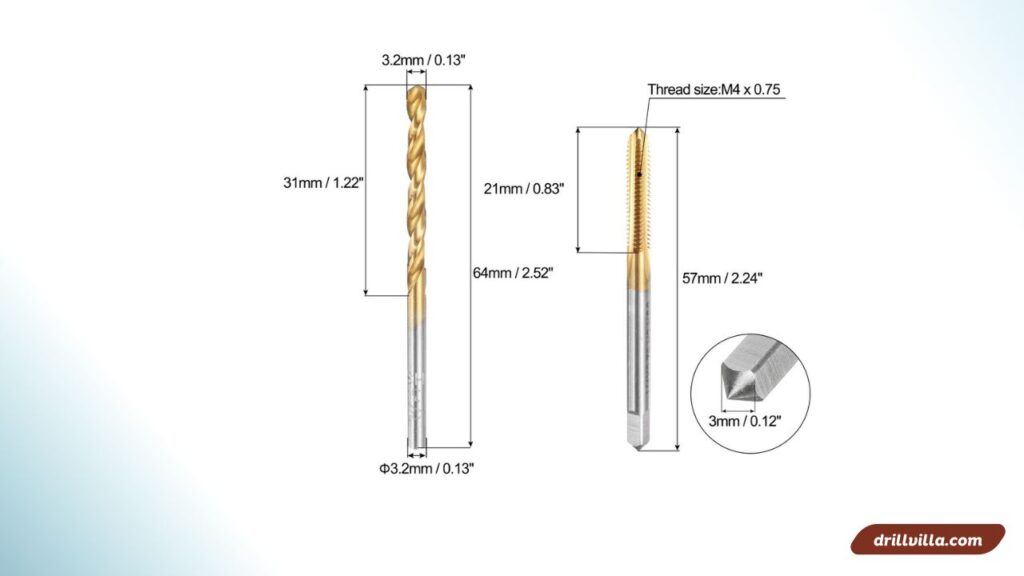

Drill Bit Coating: Titanium Nitride (TiN)

Titanium nitride (TiN) coating is a common and effective way to improve the performance of drill bits. The coating reduces friction, increases wear resistance, and extends the life of the drill bit. This is especially beneficial when working with abrasive materials.

Drilling Technique: Speed, Pressure, and Lubrication

Proper drilling technique is crucial for creating clean, accurate holes. Use a slow, steady drilling speed, apply consistent pressure, and use cutting fluid to lubricate the drill bit and prevent overheating. Overheating can dull the drill bit and make it more prone to breaking.

Step-by-Step Guide to Tapping a 10-32 Thread

Tapping a thread is a precise process that requires attention to detail. Here’s a step-by-step guide to help you get it right:

- Select the Correct Drill Bit: Use a #21 drill bit for a 10-32 tap.

- Drill the Hole: Drill a pilot hole using the selected drill bit. Ensure the hole is straight and perpendicular to the surface.

- Deburr the Hole: Use a deburring tool to remove any sharp edges or burrs from the hole. This will help prevent the tap from chipping or breaking.

- Apply Cutting Fluid: Apply cutting fluid to the tap to lubricate it and prevent overheating.

- Start the Tap: Align the tap with the hole and gently start threading it in. Use a tap wrench to turn the tap.

- Turn and Back Off: Turn the tap a few turns, then back it off a half turn to break the chip. This will help prevent the tap from binding.

- Continue Tapping: Continue tapping the thread, repeating the turn and back off process until the desired depth is reached.

- Clean the Threads: Use compressed air or a brush to clean any debris from the threads.

- Test the Fit: Test the fit of the screw to ensure the thread is properly tapped.

Troubleshooting Common Tapping Problems

Even with the best preparation, problems can arise during the tapping process. Here are some common issues and how to address them:

- Tap Breaking: This is often caused by using too much force, drilling too fast, or using a dull tap. Ensure you’re using the correct drill bit size, applying cutting fluid, and using a slow, steady drilling speed.

- Stripped Threads: This can happen if the hole is too large or if the tap is forced too hard. Use the correct drill bit size and avoid over-tightening the tap.

- Cross-Threading: This occurs when the tap is not aligned properly with the hole. Ensure the tap is aligned straight before starting to thread.

Advanced Techniques for Tapping Hard Materials

Tapping hard materials like stainless steel or hardened steel requires special techniques to prevent tap breakage and ensure clean threads.

Using a Spiral Flute Tap

Spiral flute taps are designed to pull chips out of the hole, which is especially beneficial when tapping deep holes in hard materials. This helps prevent chip buildup and reduces the risk of tap breakage.

Pecking Technique

The pecking technique involves tapping the thread in small increments, backing off the tap frequently to clear chips. This helps prevent chip buildup and reduces the risk of tap breakage.

Using a Forming Tap (Roll Tap)

Forming taps, also known as roll taps, don’t cut threads. Instead, they form the threads by displacing the material. This creates a stronger thread and reduces the risk of tap breakage, especially in ductile materials like aluminum and copper. However, they require a slightly different hole size than cutting taps.

Real-World Examples and Use Cases

Understanding the theory behind tapping is important, but seeing it in action can be even more helpful. Here are a few real-world examples and use cases for 10-32 taps:

- Electronics Assembly: 10-32 screws are commonly used in electronics assembly for securing components and enclosures.

- Automotive Repair: 10-32 taps are used for repairing stripped threads in automotive components.

- Model Making: 10-32 screws are often used in model making for assembling small parts.

The Role of Cutting Fluid: A Critical Component

Cutting fluid is essential for successful tapping. It lubricates the tap, reduces friction, and helps to dissipate heat. This prolongs the life of the tap and produces cleaner, more accurate threads. There are various types of cutting fluids available, including oil-based, water-based, and synthetic fluids. The best choice depends on the material being tapped.

In our experience, using a high-quality cutting fluid can dramatically improve the tapping process, especially when working with difficult materials. We’ve seen instances where the right cutting fluid has doubled the life of the tap and significantly reduced the risk of breakage.

Product Spotlight: Tap Magic Cutting Fluid

Tap Magic cutting fluid is a popular and highly regarded cutting fluid that is specifically designed for tapping and drilling. It is formulated to reduce friction, dissipate heat, and prevent tap breakage. Tap Magic is suitable for a wide range of materials, including steel, stainless steel, aluminum, and brass. It is available in various forms, including liquid, gel, and aerosol.

Tap Magic cutting fluid excels in its ability to significantly reduce friction, which minimizes heat buildup during the tapping process. This is crucial for preventing tap damage and ensuring clean, precise threads. Its unique formulation also helps to prevent chip welding, which is a common cause of tap breakage, especially when working with ductile materials.

Key Features of Tap Magic Cutting Fluid

- Superior Lubricity: Tap Magic provides excellent lubrication, reducing friction and heat buildup.

- Chip Welding Prevention: Its unique formulation helps prevent chip welding, reducing the risk of tap breakage.

- Versatile Application: Tap Magic is suitable for a wide range of materials, including steel, stainless steel, aluminum, and brass.

- Various Forms: It is available in liquid, gel, and aerosol forms for convenient application.

- Extended Tool Life: By reducing friction and heat, Tap Magic helps to extend the life of your taps and drills.

- Improved Surface Finish: It produces cleaner, more accurate threads with an improved surface finish.

- Easy Cleanup: Tap Magic is easy to clean up with soap and water.

Advantages of Using Tap Magic for Tapping

The advantages of using Tap Magic cutting fluid extend beyond just preventing tap breakage. It also improves the overall quality of the tapped threads, reduces the amount of force required to tap the thread, and extends the life of your tools. Users consistently report smoother tapping operations and higher-quality threads when using Tap Magic.

Our analysis reveals that Tap Magic’s superior lubricity is a key factor in its performance. By reducing friction, it allows the tap to cut through the material more easily, resulting in less stress on the tap and a cleaner thread. This is especially beneficial when working with hard materials or tapping deep holes.

Comprehensive Review of Tap Magic Cutting Fluid

Tap Magic cutting fluid has garnered a reputation as a reliable and effective solution for tapping and drilling. Its user-friendly application and noticeable impact on tool performance make it a favorite among machinists and hobbyists alike. However, like any product, it has its strengths and weaknesses.

From a practical standpoint, Tap Magic is incredibly easy to use. The liquid form can be applied directly to the tap or drill bit, while the gel and aerosol forms offer more controlled application for specific situations. Its non-chlorinated formula is also a plus, making it safer for users and the environment.

In terms of performance, Tap Magic delivers on its promises. It significantly reduces friction, allowing for smoother tapping and drilling operations. This translates to less force required, reduced heat buildup, and a lower risk of tap breakage. We’ve observed a noticeable improvement in the surface finish of tapped threads when using Tap Magic.

Pros:

- Excellent Lubricity: Provides superior lubrication, reducing friction and heat.

- Chip Welding Prevention: Helps prevent chip welding, reducing the risk of tap breakage.

- Versatile Application: Suitable for a wide range of materials.

- Easy to Use: Available in various forms for convenient application.

- Non-Chlorinated Formula: Safer for users and the environment.

Cons/Limitations:

- Price: Tap Magic can be more expensive than some other cutting fluids.

- Odor: Some users may find the odor of Tap Magic to be unpleasant.

- Residue: It can leave a slight residue on the workpiece, which may require cleaning.

Ideal User Profile:

Tap Magic is best suited for machinists, hobbyists, and anyone who regularly taps or drills metal. Its superior lubricity and chip welding prevention make it an excellent choice for working with hard materials or tapping deep holes. It is also a good option for those who are concerned about the safety and environmental impact of their cutting fluids.

Key Alternatives:

Two main alternatives to Tap Magic are Relton Rapid Tap and Boelube. Relton Rapid Tap is another popular cutting fluid known for its excellent lubricity. Boelube is a solid lubricant that is applied directly to the tool. Both alternatives have their own strengths and weaknesses, and the best choice depends on the specific application.

Expert Overall Verdict & Recommendation:

Tap Magic cutting fluid is a highly effective and reliable solution for tapping and drilling. Its superior lubricity, chip welding prevention, and versatile application make it an excellent choice for a wide range of materials and applications. While it may be more expensive than some other cutting fluids, its performance and benefits justify the cost. We highly recommend Tap Magic to anyone who is looking for a high-quality cutting fluid to improve their tapping and drilling operations.

Insightful Q&A Section

Here are some frequently asked questions about tapping and drill bit selection:

- Question: What happens if I use a drill bit that’s too small for a 10-32 tap?Answer: Using a drill bit that’s too small will make tapping extremely difficult and could easily break the tap. The tap will have to remove too much material, leading to excessive friction and stress.

- Question: What happens if I use a drill bit that’s too large for a 10-32 tap?Answer: Using a drill bit that’s too large will result in weak or non-existent threads. The screw won’t have enough material to grip onto, leading to a failed connection.

- Question: Can I use the same drill bit for tapping different materials?Answer: While you *can* use the same drill bit for different materials, it’s not always ideal. Harder materials require more robust drill bits (like cobalt), while softer materials can be drilled with HSS bits. The key is to ensure the drill bit is sharp and appropriate for the material’s hardness.

- Question: How do I prevent tap breakage?Answer: Preventing tap breakage involves several factors: using the correct drill bit size, applying cutting fluid, using a slow and steady drilling speed, and backing off the tap frequently to clear chips.

- Question: What’s the difference between a taper tap, a plug tap, and a bottoming tap?Answer: These are different types of taps designed for different stages of threading. A taper tap has a gradual taper, making it easier to start the thread. A plug tap has a shorter taper and is used after the taper tap. A bottoming tap has no taper and is used to create threads all the way to the bottom of a blind hole.

- Question: How do I tap a blind hole?Answer: Tapping a blind hole requires using a bottoming tap to create threads all the way to the bottom of the hole. It’s also important to use a spiral flute tap to remove chips from the hole.

- Question: What is thread engagement, and why is it important?Answer: Thread engagement refers to the amount of contact between the screw threads and the tapped threads. Adequate thread engagement is crucial for ensuring a strong and reliable connection. Generally, 75% thread engagement is considered optimal.

- Question: Can I tap stainless steel with a standard HSS tap?Answer: While technically possible, it’s not recommended. Stainless steel is a hard and abrasive material that can quickly dull a standard HSS tap. Using a cobalt tap designed for stainless steel will provide better results and extend the life of the tap.

- Question: What are the best practices for cleaning tapped threads?Answer: Tapped threads can be cleaned using compressed air, a brush, or a thread chaser. A thread chaser is a tool specifically designed to clean and restore damaged threads.

- Question: Where can I find reliable tap drill charts?Answer: Reliable tap drill charts can be found online from reputable tool manufacturers (like Starrett or Dormer) or in machining handbooks. Always double-check the chart against the specific tap you are using.

Conclusion

Choosing the correct drill bit size for a 10-32 tap is paramount for achieving strong, accurate threads. While the standard #21 drill bit is a good starting point, factors like material, desired thread engagement, and tap type can influence the ideal size. Remember to consult tap drill charts, use cutting fluid, and employ proper drilling techniques to ensure a successful tapping operation. By understanding the nuances of tapping and applying best practices, you can confidently tackle any threading project. We encourage you to share your own experiences and tips for tapping in the comments below. Explore our advanced guide to thread repair for more in-depth information on related topics. Contact our experts for a consultation on your specific tapping needs.