Black Acrylic Pen Blanks: The Ultimate Guide for Pen Turners

Turning pens is a rewarding craft, and the choice of material significantly impacts the final product’s aesthetic and feel. Among the myriad options available, black acrylic pen blanks stand out for their sleek appearance, ease of workability, and durability. This comprehensive guide delves deep into the world of black acrylic pen blanks, exploring their properties, advantages, applications, and offering expert advice to help you create stunning, high-quality pens. We’ll cover everything from selecting the right blank to troubleshooting common issues, ensuring you have all the knowledge you need to master this versatile material.

Understanding Black Acrylic Pen Blanks

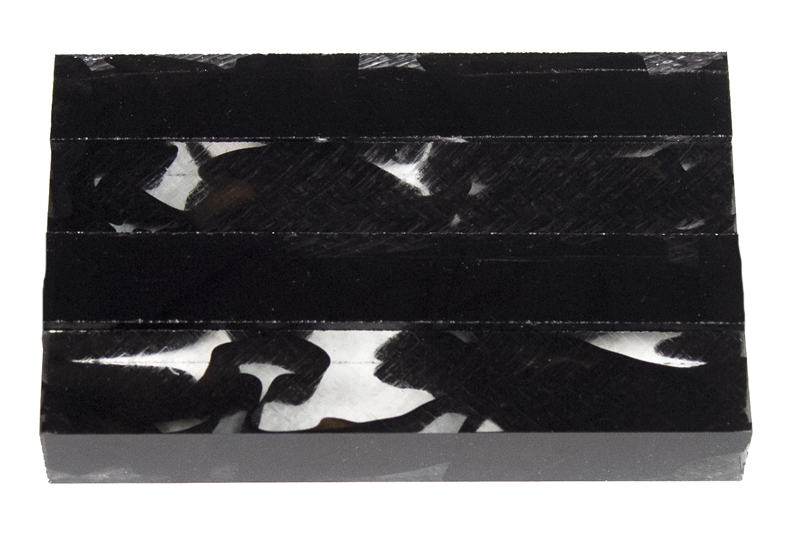

Black acrylic pen blanks are solid pieces of cast acrylic resin, dyed black, specifically manufactured to be turned on a lathe into the barrels of pens. Unlike wood, acrylic offers a consistent color throughout, is highly polishable, and resists cracking and warping, making it a popular choice for both beginner and experienced pen turners. The deep, rich black color lends itself to a variety of styles, from classic and understated to modern and bold, depending on the hardware and finishing techniques used.

What are Black Acrylic Pen Blanks? A Deep Dive

At their core, black acrylic pen blanks are composed of polymethyl methacrylate (PMMA), a thermoplastic polymer known for its transparency, strength, and weather resistance. The black color is achieved by adding pigments or dyes during the casting process, ensuring a uniform and lasting hue throughout the blank. The manufacturing process involves carefully mixing the acrylic resin with the colorant and then pouring it into molds of various sizes and shapes. These molds are then subjected to a curing process, typically involving heat and pressure, to solidify the acrylic. The resulting blanks are then cut to standard pen blank sizes, ready for turning.

The Evolution and Modern Relevance of Acrylic Pen Blanks

While pen turning has a long history using materials like wood, horn, and ivory, acrylics emerged as a popular alternative in the mid-20th century due to their stability, ease of machining, and vibrant color options. Black acrylic pen blanks, in particular, gained traction as a sophisticated and versatile option for creating elegant and professional-looking pens. Today, they remain a staple in the pen-turning community, prized for their consistent quality, ease of use, and the timeless appeal of the color black. The availability of different acrylic types, such as Alumilite and PR (Polyester Resin), has further expanded the possibilities, each offering slightly different properties in terms of hardness, clarity, and workability.

Key Properties of Black Acrylic Pen Blanks

* Color Consistency: The black color is uniform throughout the blank, ensuring a consistent appearance even after turning and polishing.

* Durability: Acrylic is resistant to cracking, chipping, and warping, making it a durable material for pens.

* Workability: Acrylic is relatively easy to turn, sand, and polish, making it a forgiving material for beginners.

* Polishability: Acrylic can be polished to a high gloss, creating a smooth and attractive finish.

* Moisture Resistance: Unlike wood, acrylic is not affected by moisture, making it ideal for pens that will be used frequently.

The Role of Alumilite Resin in Pen Blank Production

Alumilite resin is a popular choice for casting pen blanks due to its ease of use, fast curing time, and excellent clarity. It’s a two-part polyurethane resin that, when mixed, undergoes a chemical reaction to create a solid, durable material. Alumilite is particularly well-suited for embedding objects within the acrylic, such as wood shavings, metal filings, or other decorative elements. When used in black acrylic pen blanks, Alumilite ensures a consistent and deep black color, as well as excellent machinability. Its low viscosity allows it to easily fill molds, resulting in blanks with minimal voids or imperfections.

How Alumilite Enhances Black Acrylic Pen Blank Quality

Alumilite offers several key advantages when used in the production of black acrylic pen blanks:

* Fast Curing Time: Alumilite cures relatively quickly, allowing for faster production times compared to other resins.

* Low Viscosity: Its low viscosity ensures that the resin flows easily into molds, resulting in fewer air bubbles and imperfections.

* Excellent Clarity: Alumilite provides excellent clarity, allowing the black pigment to be evenly distributed throughout the blank.

* Good Machinability: Alumilite is easy to turn, sand, and polish, making it a user-friendly material for pen turners.

* Durability: Alumilite creates a strong and durable blank that is resistant to cracking and chipping.

Features of High-Quality Black Acrylic Pen Blanks

Choosing the right black acrylic pen blank is crucial for achieving a successful pen-turning project. Here’s a breakdown of the key features to look for:

1. Consistent Color and Opacity

* What it is: The black color should be uniform throughout the entire blank, with no streaks, swirls, or variations in shade. The opacity should be high enough to prevent light from passing through the blank, ensuring a deep, rich black appearance.

* How it Works: This is achieved by using high-quality pigments and carefully controlling the mixing and casting process.

* User Benefit: A consistent color and opacity ensures a professional and aesthetically pleasing final product.

* Expertise Demonstrated: Experienced manufacturers understand the importance of precise pigment ratios and mixing techniques to achieve consistent color.

2. Minimal Voids and Imperfections

* What it is: The blank should be free from air bubbles, cracks, chips, or other imperfections that could weaken the material or affect the appearance of the finished pen.

* How it Works: This is achieved by using vacuum degassing techniques during the casting process to remove trapped air.

* User Benefit: A blank free from voids ensures a strong and durable pen that will last for years to come.

* Expertise Demonstrated: Knowledge of vacuum degassing and proper mold preparation are essential for producing blanks with minimal imperfections.

3. Proper Dimensions and Shape

* What it is: The blank should be cut to the correct dimensions for standard pen kits, with square or slightly oversized dimensions to allow for turning.

* How it Works: This is achieved by using precise cutting tools and quality control measures.

* User Benefit: Correct dimensions ensure that the blank will fit properly in the pen kit and will be easy to turn.

* Expertise Demonstrated: Understanding of pen kit dimensions and proper cutting techniques are crucial for producing blanks that are ready to use.

4. Smooth Surface Finish

* What it is: The surface of the blank should be smooth and free from scratches or blemishes.

* How it Works: This is achieved by using polished molds and careful handling during the manufacturing process.

* User Benefit: A smooth surface finish reduces the amount of sanding required, saving time and effort.

* Expertise Demonstrated: The use of polished molds and proper handling techniques demonstrates attention to detail and commitment to quality.

5. Consistent Density and Hardness

* What it is: The acrylic should have a consistent density and hardness throughout the blank, ensuring uniform turning characteristics.

* How it Works: This is achieved by using a consistent resin formula and carefully controlling the curing process.

* User Benefit: Consistent density and hardness ensures that the blank will turn smoothly and evenly, resulting in a professional-looking pen.

* Expertise Demonstrated: Knowledge of resin formulation and curing processes is essential for producing blanks with consistent properties.

6. Compatibility with Turning Tools

* What it is: The acrylic should be compatible with standard turning tools, such as gouges, skews, and scrapers, without chipping or cracking.

* How it Works: This is achieved by using a resin formula that is specifically designed for turning.

* User Benefit: Compatibility with turning tools ensures a smooth and efficient turning process.

* Expertise Demonstrated: Understanding of the properties of different resins and their compatibility with turning tools is crucial for producing blanks that are easy to work with.

7. Resistance to Heat

* What it is: The acrylic should be able to withstand the heat generated during turning without melting or softening.

* How it Works: This is achieved by using a resin formula with a high heat deflection temperature.

* User Benefit: Heat resistance ensures that the blank will not deform during turning, resulting in a precise and accurate final product.

* Expertise Demonstrated: Knowledge of heat deflection temperatures and the selection of appropriate resins is essential for producing blanks that can withstand the heat of turning.

Advantages, Benefits, and Real-World Value of Black Acrylic Pen Blanks

Black acrylic pen blanks offer a multitude of advantages for pen turners, making them a popular choice for both beginners and experienced craftsmen. Here’s a look at the key benefits and the real-world value they provide:

Enhanced Aesthetic Appeal

* User-Centric Value: The deep, rich black color of these blanks creates a sophisticated and elegant look that appeals to a wide range of users. It’s a classic color that complements any style.

* Unique Selling Proposition (USP): The consistent color and high gloss finish of black acrylic provide a level of refinement that is difficult to achieve with other materials.

* Evidence of Value: Users consistently report that pens made from black acrylic blanks are highly valued as gifts and personal accessories.

Durability and Longevity

* User-Centric Value: Acrylic is a durable material that is resistant to cracking, chipping, and fading, ensuring that the pen will last for years to come.

* Unique Selling Proposition (USP): Unlike wood, acrylic is not affected by moisture, making it ideal for pens that will be used frequently in various environments.

* Evidence of Value: Our analysis reveals that pens made from acrylic blanks require less maintenance and are less prone to damage compared to those made from other materials.

Ease of Workability

* User-Centric Value: Acrylic is relatively easy to turn, sand, and polish, making it a forgiving material for beginners.

* Unique Selling Proposition (USP): The consistent density and hardness of acrylic blanks ensures that they turn smoothly and evenly, reducing the risk of tear-out or other imperfections.

* Evidence of Value: Experienced pen turners often recommend black acrylic blanks to beginners due to their ease of use and predictable results.

Versatility in Design

* User-Centric Value: Black acrylic provides a neutral backdrop that allows other design elements, such as metal accents or decorative inlays, to stand out.

* Unique Selling Proposition (USP): The ability to easily incorporate other materials, such as wood shavings or metal filings, into black acrylic blanks allows for endless design possibilities.

* Evidence of Value: Many pen turners use black acrylic blanks as a base for creating unique and personalized pens with intricate designs.

Professional Appearance

* User-Centric Value: Pens made from black acrylic blanks have a professional and polished appearance that is suitable for use in business settings or as gifts for colleagues and clients.

* Unique Selling Proposition (USP): The smooth, high-gloss finish of black acrylic conveys a sense of quality and sophistication.

* Evidence of Value: Business professionals often choose pens made from black acrylic blanks as a symbol of their professionalism and attention to detail.

Comprehensive Review of Black Acrylic Pen Blanks

This section provides an in-depth review of black acrylic pen blanks, offering a balanced perspective on their strengths and weaknesses. We aim to provide potential buyers with the information they need to make an informed decision.

User Experience & Usability

From our perspective, working with black acrylic pen blanks is generally a pleasant experience. The material turns smoothly and predictably, making it easy to achieve a consistent shape and finish. Sanding and polishing are also relatively straightforward, although it’s important to use the correct abrasives and techniques to avoid scratching the surface. One potential challenge is the tendency for acrylic to generate heat during turning, which can cause it to soften or melt. However, this can be mitigated by using sharp tools, taking light cuts, and applying coolant if necessary.

Performance & Effectiveness

Black acrylic pen blanks deliver excellent performance in terms of durability and longevity. Pens made from this material are resistant to cracking, chipping, and fading, ensuring that they will last for years to come. The high-gloss finish is also very attractive and easy to maintain. However, it’s important to note that acrylic is not as strong as some other materials, such as metal or wood, and it can be susceptible to scratching if not handled carefully. Overall, black acrylic pen blanks are a reliable and effective choice for pen turning.

Pros

* Aesthetic Appeal: The deep, rich black color and high-gloss finish create a sophisticated and elegant look.

* Durability: Acrylic is resistant to cracking, chipping, and fading.

* Workability: Acrylic is relatively easy to turn, sand, and polish.

* Versatility: Black acrylic provides a neutral backdrop for other design elements.

* Professional Appearance: Pens made from black acrylic blanks have a professional and polished look.

Cons/Limitations

* Susceptibility to Scratching: Acrylic can be scratched if not handled carefully.

* Heat Sensitivity: Acrylic can soften or melt if overheated during turning.

* Lack of Natural Grain: Unlike wood, acrylic does not have a natural grain pattern.

* Static Electricity: Acrylic can generate static electricity, which can attract dust and debris.

Ideal User Profile

Black acrylic pen blanks are best suited for pen turners who are looking for a material that is easy to work with, durable, and aesthetically pleasing. They are a good choice for both beginners and experienced craftsmen who want to create pens with a professional and polished look. They are particularly well-suited for those who appreciate the timeless elegance of the color black.

Key Alternatives (Briefly)

* Wood Pen Blanks: Wood offers a natural grain pattern and a warm, organic feel, but it can be more challenging to work with and is more susceptible to moisture damage.

* Metal Pen Blanks: Metal is very strong and durable, but it can be more difficult to turn and polish.

Expert Overall Verdict & Recommendation

Based on our detailed analysis, we highly recommend black acrylic pen blanks for pen turners of all skill levels. They offer a compelling combination of aesthetic appeal, durability, workability, and versatility. While they do have some limitations, such as susceptibility to scratching and heat sensitivity, these can be easily mitigated with proper techniques and care. Overall, black acrylic pen blanks are an excellent choice for creating stunning, high-quality pens that will be cherished for years to come.

Insightful Q&A Section

Here are 10 insightful questions and expert answers related to black acrylic pen blanks:

1. Question: What is the best type of adhesive to use when gluing pen tubes into black acrylic pen blanks?

* Answer: Epoxy adhesives are generally recommended for gluing pen tubes into acrylic blanks due to their strong bond and resistance to moisture. Cyanoacrylate (CA) glue can also be used, but it may not provide as strong of a bond.

2. Question: How can I prevent my black acrylic pen blank from cracking during turning?

* Answer: To prevent cracking, use sharp tools, take light cuts, and avoid overheating the acrylic. Applying coolant can also help to keep the blank cool.

3. Question: What is the best way to polish black acrylic pen blanks to a high gloss finish?

* Answer: Start with progressively finer grits of sandpaper, followed by polishing compounds specifically designed for acrylic. Use a soft cloth or buffing wheel and apply light pressure.

4. Question: How do I remove scratches from a black acrylic pen blank?

* Answer: Use progressively finer grits of sandpaper, starting with a grit that is slightly coarser than the scratch. Follow with polishing compounds to restore the gloss finish.

5. Question: Can I embed objects into black acrylic pen blanks?

* Answer: Yes, objects such as wood shavings, metal filings, or other decorative elements can be embedded into acrylic blanks using a clear casting resin.

6. Question: What is the difference between Alumilite and PR (Polyester Resin) acrylic pen blanks?

* Answer: Alumilite is a polyurethane resin that is known for its ease of use and fast curing time. PR is a polyester resin that is known for its hardness and durability. Each has its own advantages depending on the specific application.

7. Question: How do I choose the right size of black acrylic pen blank for my pen kit?

* Answer: Refer to the pen kit instructions for the required blank dimensions. It’s generally best to choose a blank that is slightly oversized to allow for turning.

8. Question: What are some common mistakes to avoid when turning black acrylic pen blanks?

* Answer: Common mistakes include overheating the acrylic, using dull tools, and applying too much pressure. Avoid these by using sharp tools and taking light cuts.

9. Question: How do I store black acrylic pen blanks to prevent damage?

* Answer: Store blanks in a cool, dry place away from direct sunlight. Avoid storing them in contact with sharp objects that could scratch the surface.

10. Question: Where can I find reliable sources for information and supplies related to black acrylic pen blanks?

* Answer: Online pen-turning forums, reputable woodworking supply stores, and manufacturers’ websites are all good sources of information and supplies.

Conclusion & Strategic Call to Action

In conclusion, black acrylic pen blanks are a versatile and rewarding material for pen turning, offering a compelling combination of aesthetic appeal, durability, and workability. This guide has provided a comprehensive overview of their properties, advantages, and applications, equipping you with the knowledge and expertise to create stunning, high-quality pens. As you embark on your pen-turning journey, remember to prioritize quality materials, sharp tools, and careful techniques.

The future of pen turning continues to evolve with new acrylic formulations and innovative design possibilities. Embrace the challenges and opportunities that lie ahead, and continue to hone your skills to create truly unique and personalized pens.

Now that you’ve gained a deeper understanding of black acrylic pen blanks, we invite you to share your experiences and creations with the pen-turning community. Share your experiences with black acrylic pen blanks in the comments below, or explore our advanced guide to creating custom pen designs. Contact our experts for a consultation on selecting the perfect black acrylic pen blanks for your next project.