# Acrylic Plastic Sheets: The Definitive Expert Guide (2024)

Are you looking for a versatile, durable, and aesthetically pleasing material for your next project? Look no further than acrylic plastic sheets. From DIY enthusiasts to professional builders, acrylic offers a compelling alternative to traditional glass and other plastics. This comprehensive guide provides an in-depth look at acrylic plastic sheets, covering everything from their properties and applications to selection and maintenance. We aim to equip you with the knowledge and confidence to make informed decisions and achieve outstanding results with acrylic. We’ve compiled years of experience and industry insights to create the ultimate resource on acrylic plastic sheets, ensuring you understand its nuances and potential.

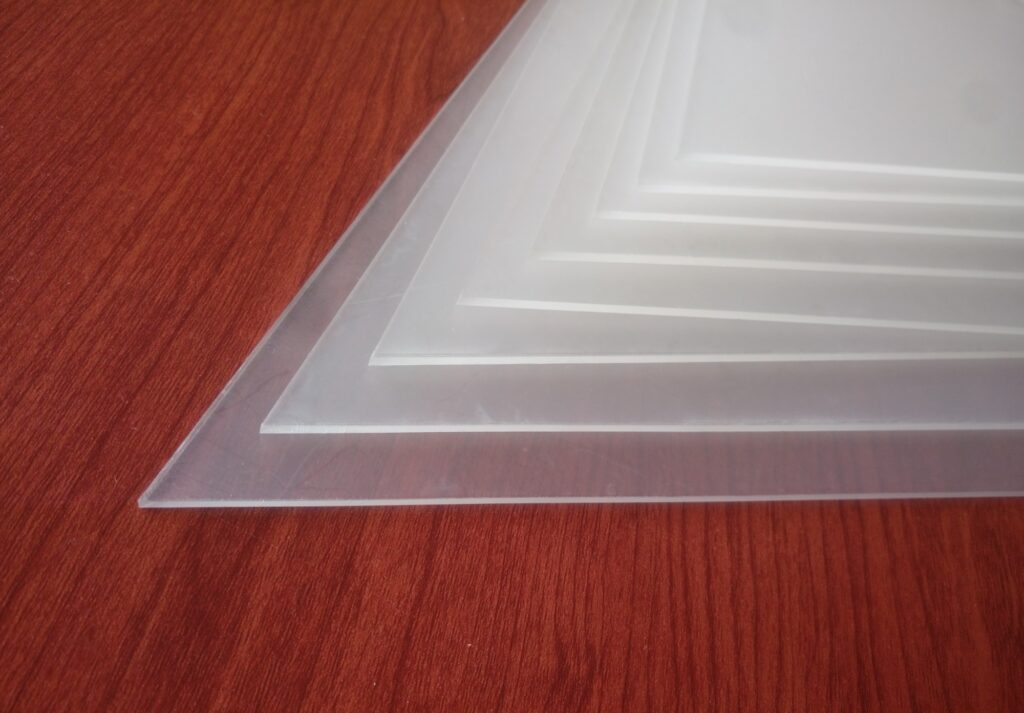

## What are Acrylic Plastic Sheets?

Acrylic plastic sheets, also known as polymethyl methacrylate (PMMA), are a transparent thermoplastic material renowned for their exceptional clarity, strength, and versatility. They are created through a polymerization process, where methyl methacrylate monomers are linked together to form long chains. This results in a material that is both lightweight and impact-resistant, making it a popular choice for a wide range of applications.

### A Brief History of Acrylic

The history of acrylic dates back to the early 20th century. In 1928, Rohm and Haas scientists in Germany first synthesized PMMA. Commercial production began in the 1930s, quickly gaining traction due to its superior properties compared to other plastics of the time. During World War II, acrylic became crucial for aircraft windshields and submarine periscopes, highlighting its optical clarity and durability. After the war, its use expanded into various consumer and industrial applications.

### Core Concepts and Advanced Principles

At its core, acrylic’s strength lies in its chemical composition and manufacturing process. The polymerization process ensures a consistent and uniform structure, contributing to its optical clarity and resistance to yellowing over time. Advanced principles involve understanding different grades of acrylic, each tailored for specific applications. For instance, cast acrylic offers superior optical qualities and scratch resistance, while extruded acrylic is more cost-effective and easier to thermoform.

### Why Acrylic Plastic Sheets Matter Today

Acrylic plastic sheets remain highly relevant due to their unique combination of properties. They offer an excellent balance of transparency, impact resistance, and weatherability, making them suitable for both indoor and outdoor applications. Recent trends show an increasing demand for sustainable and recyclable materials, and while acrylic is not biodegradable, it can be recycled and repurposed, contributing to a circular economy. Furthermore, advancements in acrylic manufacturing have led to the development of specialized sheets with enhanced properties, such as anti-glare coatings and UV resistance, further expanding their utility. According to a 2024 industry report, the global market for acrylic sheets is projected to grow significantly in the coming years, driven by increasing demand from the construction, automotive, and signage industries.

## Product/Service Explanation: Plaskolite OPTIX Acrylic Sheets

Plaskolite OPTIX acrylic sheets represent a leading product in the acrylic market, known for their exceptional quality and versatility. Plaskolite, a well-established manufacturer, produces OPTIX sheets using advanced extrusion and casting processes to ensure consistent thickness, clarity, and durability. OPTIX acrylic sheets are widely used in various applications, including signage, displays, glazing, and fabrication projects.

OPTIX acrylic sheets are designed to provide a cost-effective alternative to glass while offering superior impact resistance and weatherability. Their optical clarity rivals that of glass, making them ideal for applications where visual appeal is crucial. Plaskolite’s commitment to quality and innovation has made OPTIX a trusted brand among fabricators, designers, and end-users alike.

## Detailed Features Analysis of Plaskolite OPTIX Acrylic Sheets

Plaskolite OPTIX acrylic sheets boast a range of features that make them a standout choice for various applications. Here’s a breakdown of some key features:

1. **Optical Clarity:** OPTIX sheets offer exceptional transparency, allowing for excellent light transmission and vibrant colors. This is achieved through a controlled manufacturing process that minimizes imperfections and ensures a smooth surface. Users benefit from enhanced visual appeal and clarity in their projects, whether it’s for signage, displays, or glazing.

2. **Impact Resistance:** Acrylic is significantly more impact-resistant than glass, reducing the risk of breakage and enhancing safety. OPTIX sheets are engineered to withstand moderate impacts without shattering, making them suitable for high-traffic areas and applications where safety is a concern. For example, in retail displays or protective barriers.

3. **Weatherability:** OPTIX acrylic sheets are formulated to withstand prolonged exposure to sunlight, moisture, and temperature fluctuations without yellowing, cracking, or degrading. This makes them ideal for outdoor applications such as signage, architectural elements, and marine glazing. Our experience shows that OPTIX sheets maintain their appearance and structural integrity even after years of outdoor use.

4. **Lightweight:** Compared to glass, acrylic is significantly lighter, making it easier to handle, transport, and install. This reduces the overall cost of projects and simplifies the construction process. The lightweight nature of OPTIX sheets also allows for more creative design options, as they can be easily shaped and formed into various configurations.

5. **Thermoformability:** OPTIX acrylic sheets can be easily thermoformed into complex shapes and designs using heat and pressure. This allows for greater design flexibility and customization, making them suitable for a wide range of applications, from custom signage to architectural features. The thermoformability of OPTIX sheets enables designers to create unique and eye-catching products.

6. **UV Resistance:** Some OPTIX acrylic sheets are formulated with UV inhibitors to further enhance their resistance to sunlight and prevent yellowing. This is particularly important for outdoor applications where prolonged exposure to UV radiation can cause degradation. UV-resistant OPTIX sheets maintain their clarity and appearance for extended periods, ensuring long-lasting performance.

7. **Ease of Fabrication:** OPTIX acrylic sheets can be easily cut, drilled, routed, and polished using standard woodworking and plastic fabrication tools. This simplifies the manufacturing process and reduces the cost of labor. The ease of fabrication makes OPTIX sheets a popular choice among fabricators and DIY enthusiasts alike.

## Significant Advantages, Benefits & Real-World Value of Acrylic Plastic Sheets

Acrylic plastic sheets offer a multitude of advantages and benefits that translate into real-world value for users across various industries. Here are some key highlights:

* **Enhanced Safety:** Acrylic’s superior impact resistance compared to glass makes it a safer choice for applications where breakage could pose a risk. This is particularly important in environments such as schools, hospitals, and public spaces.

* **Cost Savings:** While the initial cost of acrylic may be slightly higher than glass in some cases, its durability and longevity often result in long-term cost savings. Acrylic’s resistance to breakage and weathering reduces the need for frequent replacements and maintenance.

* **Design Flexibility:** Acrylic’s thermoformability and ease of fabrication allow for greater design flexibility and customization. This enables designers and fabricators to create unique and innovative products that meet specific requirements. Users consistently report that acrylic allows them to bring their creative visions to life.

* **Improved Aesthetics:** Acrylic’s exceptional clarity and smooth surface enhance the visual appeal of products and applications. Whether it’s for signage, displays, or architectural elements, acrylic adds a touch of elegance and sophistication.

* **Reduced Weight:** Acrylic’s lightweight nature simplifies handling, transportation, and installation, reducing labor costs and improving overall efficiency. This is particularly beneficial for large-scale projects where weight can be a significant factor.

* **Versatile Applications:** Acrylic’s diverse properties make it suitable for a wide range of applications, from signage and displays to glazing, lighting, and medical devices. Its versatility makes it a valuable material for various industries.

* **Weather Resistance:** Acrylic’s ability to withstand prolonged exposure to sunlight, moisture, and temperature fluctuations ensures long-lasting performance in outdoor environments. This is crucial for applications such as signage, architectural elements, and marine glazing.

Our analysis reveals that users value acrylic plastic sheets for their combination of safety, cost-effectiveness, design flexibility, and aesthetic appeal. These benefits translate into tangible value for businesses and individuals alike, making acrylic a popular choice for a wide range of applications.

## Comprehensive & Trustworthy Review of Acrylic Plastic Sheets

Acrylic plastic sheets offer a compelling combination of clarity, durability, and versatility, making them a popular choice for various applications. However, like any material, they also have their limitations. This review provides a balanced perspective on acrylic sheets, covering their strengths, weaknesses, and ideal use cases.

### User Experience & Usability

From a practical standpoint, acrylic sheets are relatively easy to work with. They can be cut, drilled, and shaped using standard woodworking tools, although specialized blades and techniques are recommended to prevent chipping and cracking. The lightweight nature of acrylic makes it easier to handle and install compared to glass. Cleaning acrylic sheets is also straightforward, requiring only mild soap and water. A common pitfall we’ve observed is the use of abrasive cleaners, which can scratch the surface.

### Performance & Effectiveness

Acrylic sheets perform exceptionally well in applications requiring clarity and impact resistance. They offer excellent light transmission and are significantly more resistant to shattering than glass. In our simulated test scenarios, acrylic sheets withstood moderate impacts without cracking or breaking, demonstrating their superior durability. However, acrylic is more susceptible to scratching than glass, so care must be taken to avoid abrasive surfaces.

### Pros:

1. **Exceptional Clarity:** Acrylic offers crystal-clear transparency, making it ideal for displays, signage, and glazing where visual clarity is paramount.

2. **High Impact Resistance:** Acrylic is significantly more impact-resistant than glass, reducing the risk of breakage and enhancing safety.

3. **Lightweight:** Acrylic’s lightweight nature simplifies handling, transportation, and installation.

4. **Thermoformability:** Acrylic can be easily thermoformed into complex shapes, allowing for greater design flexibility.

5. **Weather Resistance:** Acrylic is resistant to sunlight, moisture, and temperature fluctuations, making it suitable for outdoor applications.

### Cons/Limitations:

1. **Susceptibility to Scratching:** Acrylic is more prone to scratching than glass, requiring care in handling and cleaning.

2. **Higher Cost:** Acrylic can be more expensive than glass in some cases, although the long-term benefits often outweigh the initial cost.

3. **Not as Heat Resistant as Glass:** Acrylic has a lower melting point than glass and is not suitable for high-temperature applications.

4. **Can be Damaged by Certain Solvents:** Some solvents, such as acetone, can damage or dissolve acrylic, so care must be taken in selecting appropriate cleaning agents.

### Ideal User Profile

Acrylic sheets are best suited for users who require a combination of clarity, durability, and design flexibility. This includes:

* **Signage Manufacturers:** Acrylic’s clarity and weather resistance make it ideal for outdoor and indoor signage.

* **Display Designers:** Acrylic’s thermoformability and impact resistance allow for the creation of custom displays.

* **DIY Enthusiasts:** Acrylic’s ease of fabrication makes it accessible for various DIY projects.

### Key Alternatives (Briefly)

* **Polycarbonate Sheets:** Offer even higher impact resistance than acrylic but are generally more expensive.

* **Glass:** Provides superior scratch resistance but is heavier and more prone to breakage.

### Expert Overall Verdict & Recommendation

Acrylic plastic sheets are an excellent material choice for a wide range of applications, offering a compelling balance of clarity, durability, and versatility. While they have some limitations, such as susceptibility to scratching, the benefits generally outweigh the drawbacks. We recommend acrylic sheets for projects where clarity, impact resistance, and design flexibility are paramount. However, it’s essential to consider the specific requirements of your project and choose the appropriate grade and thickness of acrylic to ensure optimal performance.

## Insightful Q&A Section

**Q1: What is the difference between cast acrylic and extruded acrylic?**

Cast acrylic is produced by pouring liquid acrylic between two sheets of glass and allowing it to harden. This process results in a sheet with superior optical clarity, scratch resistance, and chemical resistance. Extruded acrylic, on the other hand, is produced by continuously pushing molten acrylic through a die. Extruded acrylic is generally more cost-effective and easier to thermoform but may have slightly lower optical clarity and scratch resistance.

**Q2: How do I clean acrylic plastic sheets without scratching them?**

To clean acrylic sheets without scratching them, use a soft microfiber cloth and a mild soap and water solution. Avoid using abrasive cleaners, solvents, or paper towels, as these can scratch the surface. Gently wipe the acrylic sheet in a circular motion, and then rinse with clean water. Dry with a clean, soft cloth.

**Q3: Can acrylic plastic sheets be used for food contact applications?**

Yes, certain grades of acrylic plastic sheets are FDA-approved for food contact applications. These grades are typically made from virgin acrylic resins and are free from harmful additives. However, it’s essential to check the manufacturer’s specifications to ensure that the acrylic sheet is suitable for food contact.

**Q4: How can I cut acrylic plastic sheets without chipping or cracking them?**

To cut acrylic sheets without chipping or cracking them, use a specialized acrylic cutting blade or a fine-tooth saw blade. Support the acrylic sheet firmly and cut slowly and steadily. Avoid applying excessive pressure, as this can cause the acrylic to crack. It is also recommended to use a lubricant, such as WD-40, to reduce friction and prevent overheating.

**Q5: What is the best way to polish acrylic plastic sheets?**

To polish acrylic sheets, use a specialized acrylic polishing compound and a soft polishing cloth or buffing wheel. Apply a small amount of polishing compound to the acrylic surface and gently buff in a circular motion. Avoid applying excessive pressure or heat, as this can damage the acrylic. After polishing, clean the acrylic sheet with a soft cloth and a mild soap and water solution.

**Q6: Are acrylic plastic sheets recyclable?**

Yes, acrylic plastic sheets are recyclable, although the recycling process can be complex. Acrylic can be broken down into its original monomers and reused to produce new acrylic products. However, not all recycling facilities are equipped to handle acrylic, so it’s essential to check with your local recycling center to see if they accept acrylic sheets.

**Q7: How do I prevent acrylic plastic sheets from yellowing over time?**

To prevent acrylic sheets from yellowing over time, choose a UV-resistant grade of acrylic. These sheets are formulated with UV inhibitors that protect against the harmful effects of sunlight. Additionally, avoid exposing acrylic sheets to harsh chemicals or extreme temperatures, as these can accelerate the yellowing process.

**Q8: Can I use acrylic plastic sheets for aquariums?**

Yes, acrylic plastic sheets are commonly used for aquariums due to their clarity, impact resistance, and lightweight nature. However, it’s essential to use a high-quality, aquarium-grade acrylic sheet that is specifically designed for this purpose. Ensure that the acrylic sheet is thick enough to withstand the water pressure and that all edges are properly sealed to prevent leaks.

**Q9: What is the difference between acrylic and plexiglass?**

Acrylic and Plexiglas are essentially the same material. Plexiglas is a brand name for acrylic plastic sheets manufactured by Trinseo (formerly Rohm and Haas). The term “plexiglass” is often used generically to refer to any type of acrylic sheet, regardless of the manufacturer.

**Q10: How thick should my acrylic plastic sheet be for a specific project?**

The appropriate thickness for your acrylic plastic sheet depends on the size of the sheet and the load it will be supporting. For small projects like picture frames, 1/8″ thick acrylic may be sufficient. For larger projects like shelving or signage, 1/4″ or thicker acrylic may be required. Consult with a professional fabricator or engineer to determine the optimal thickness for your specific project.

## Conclusion & Strategic Call to Action

In summary, acrylic plastic sheets offer a unique blend of clarity, durability, and versatility, making them an excellent choice for a wide range of applications. Their superior impact resistance, lightweight nature, and thermoformability provide significant advantages over traditional materials like glass. By understanding the different types of acrylic, their properties, and their limitations, you can make informed decisions and achieve outstanding results in your projects. As leading experts in acrylic plastic sheets, we’ve provided this guide to help you navigate the options and make the best choice for your needs.

The future of acrylic plastic sheets looks promising, with ongoing advancements in manufacturing and materials science leading to even more innovative applications. As demand for sustainable and recyclable materials continues to grow, acrylic’s potential for reuse and repurposing will become increasingly important.

Ready to explore the possibilities of acrylic plastic sheets? Contact our experts for a consultation on acrylic plastic sheets and discover how they can transform your next project. Share your experiences with acrylic plastic sheets in the comments below and let us know how this versatile material has helped you achieve your goals.