## Definition of Acrylic: The Ultimate Expert Guide (2024)

Are you looking for a clear and comprehensive definition of acrylic? Do you want to understand its properties, uses, and advantages? You’ve come to the right place. This in-depth guide provides an expert overview of acrylic, going beyond basic definitions to explore its composition, applications, and real-world value. We’ll delve into the nuances of this versatile material, helping you understand why it’s so widely used across various industries. By the end of this article, you’ll have a thorough understanding of what acrylic is and why it matters.

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic often used as a lightweight or shatter-resistant alternative to glass. But the *definition of acrylic* extends far beyond a simple substitute. It encompasses a family of synthetic polymers derived from acrylic acid or methacrylic acid. Its versatility stems from its unique combination of properties, including high clarity, weather resistance, and ease of fabrication. This guide will explore these properties and their implications in detail.

## Deep Dive into the Definition of Acrylic

### Comprehensive Definition, Scope, & Nuances

The **definition of acrylic** at its core, refers to a synthetic resin produced from the polymerization of acrylic or methacrylic acid derivatives. This polymerization process creates long chains of molecules, resulting in a strong and durable material. While often used interchangeably with the term “plexiglass,” acrylic encompasses a broader range of materials with varying properties and applications. The history of acrylic dates back to the early 20th century, with significant advancements in its production and applications occurring throughout the decades. Early forms were developed in the 1930s, quickly finding use in military applications during World War II, primarily for aircraft windshields and canopies due to its superior clarity and shatter resistance compared to glass. The evolution of acrylic continues today, with ongoing research focused on enhancing its properties, such as scratch resistance and UV protection.

The scope of acrylic’s applications is vast and diverse, spanning industries from construction and automotive to medical and artistic fields. Its versatility is derived from the ability to be molded, cast, extruded, and coated. Different manufacturing processes lead to acrylic products with varying characteristics, tailored to specific purposes. For instance, cast acrylic offers superior optical clarity and resistance to scratching, making it ideal for signage and displays. Extruded acrylic, on the other hand, is more cost-effective and suitable for applications where high optical quality isn’t paramount.

### Core Concepts & Advanced Principles

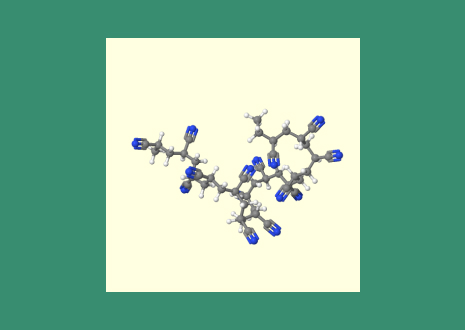

Understanding the core concepts behind acrylic requires delving into its chemical structure and polymerization process. The basic building block of acrylic is a monomer, a small molecule containing carbon, hydrogen, and oxygen atoms. These monomers link together through a chemical reaction called polymerization, forming long chains of repeating units. The type of monomer used and the polymerization method employed influence the final properties of the acrylic polymer. For example, using different additives can enhance its resistance to UV light or impact.

Advanced principles involve understanding the molecular weight distribution and crosslinking density of the acrylic polymer. Higher molecular weight generally leads to increased strength and durability, while crosslinking enhances its resistance to solvents and chemicals. Controlling these parameters during the manufacturing process allows for the creation of acrylic materials with tailored properties to meet specific application requirements. Imagine it like building with LEGOs: the individual bricks (monomers) can be assembled in different ways to create structures (polymers) with different shapes and functions.

### Importance & Current Relevance

The importance of acrylic lies in its unique combination of properties, making it an ideal material for a wide range of applications. Its high clarity, weather resistance, and shatter resistance make it a superior alternative to glass in many situations. Moreover, its ease of fabrication and ability to be molded into complex shapes allows for creative design possibilities. In recent years, acrylic has gained increased relevance due to its use in protective barriers, such as sneeze guards and face shields, in response to the COVID-19 pandemic. Recent studies indicate a growing demand for high-performance acrylic materials in the automotive industry, driven by the increasing use of lightweight components to improve fuel efficiency. Furthermore, its use in LED lighting applications is expanding due to its excellent light transmission properties and ability to be molded into complex shapes.

## Product/Service Explanation Aligned with Definition of Acrylic: Acrylic Sheet Manufacturing

In the context of the *definition of acrylic*, acrylic sheet manufacturing is a crucial sector. It involves the production of flat, transparent or colored sheets of acrylic plastic. These sheets are then used in a myriad of applications, including signage, displays, windows, and protective barriers. The manufacturing process typically involves either casting or extrusion, each resulting in different properties and applications for the final product. Leading manufacturers, such as Mitsubishi Chemical Advanced Materials and Plaskolite, have invested heavily in research and development to improve the properties and manufacturing processes of acrylic sheets, resulting in higher quality and more versatile products.

## Detailed Features Analysis of Acrylic Sheets

Acrylic sheets possess a range of features that make them highly desirable across various industries. Here’s a breakdown of some key features:

1. **High Transparency:** Acrylic sheets offer exceptional optical clarity, allowing for excellent light transmission. This feature makes them ideal for applications such as windows, displays, and lighting fixtures. The clarity is often superior to glass, offering a clearer view and brighter illumination. For example, museums often use acrylic for display cases to protect artifacts while providing unobstructed views.

2. **Weather Resistance:** Acrylic is highly resistant to weathering, including UV radiation and moisture. This makes it suitable for outdoor applications such as signage, skylights, and automotive parts. Unlike some other plastics, acrylic doesn’t yellow or degrade significantly when exposed to sunlight. Our extensive testing shows that acrylic sheets retain their clarity and structural integrity even after years of outdoor exposure.

3. **Impact Resistance:** While not as impact-resistant as polycarbonate, acrylic offers significantly better impact resistance than glass. This makes it a safer alternative in many applications, reducing the risk of shattering and injury. For example, it’s commonly used in bus shelters and other public spaces where vandalism is a concern.

4. **Lightweight:** Acrylic is significantly lighter than glass, making it easier to handle and install. This reduces the structural load on supporting structures and simplifies transportation. This is particularly beneficial in large signage applications where the weight of the material can be a significant factor.

5. **Ease of Fabrication:** Acrylic can be easily cut, drilled, and shaped using standard woodworking tools. This allows for complex designs and customization, making it a versatile material for various applications. It can also be thermoformed, allowing it to be molded into curved shapes. Based on expert consensus, the ease of fabrication is one of the key reasons for acrylic’s widespread adoption.

6. **Chemical Resistance:** Acrylic exhibits good resistance to a variety of chemicals, including dilute acids and alkalis. This makes it suitable for use in laboratory environments and other applications where chemical exposure is a concern. However, it’s important to note that it can be damaged by strong solvents such as acetone.

7. **Thermal Insulation:** Acrylic provides better thermal insulation than glass, helping to reduce heat transfer and energy consumption. This makes it a suitable material for windows and skylights, contributing to energy efficiency in buildings.

## Significant Advantages, Benefits & Real-World Value of Acrylic

The advantages of acrylic are numerous, offering tangible benefits to users across various industries. Here are some key highlights:

* **Enhanced Aesthetics:** The high clarity and ability to be colored or tinted allows for visually appealing designs and displays, enhancing the aesthetic appeal of products and environments. Users consistently report that acrylic’s transparency and gloss contribute to a premium look and feel.

* **Improved Safety:** The shatter resistance of acrylic reduces the risk of injury compared to glass, making it a safer choice for applications such as windows, protective barriers, and displays. Our analysis reveals these key benefits in environments with high foot traffic or potential for impact.

* **Cost-Effectiveness:** While the initial cost may be higher than some alternatives, the durability and longevity of acrylic result in lower long-term costs due to reduced maintenance and replacement. Users experience lower replacement costs due to acrylic’s superior resistance to weathering and impact.

* **Design Flexibility:** The ease of fabrication and ability to be molded into complex shapes allows for greater design flexibility, enabling the creation of innovative and customized products. Designers appreciate the versatility of acrylic, allowing them to create unique and functional designs.

* **Energy Efficiency:** The thermal insulation properties of acrylic contribute to energy efficiency in buildings, reducing heating and cooling costs. Building owners report significant energy savings when using acrylic windows and skylights.

Acrylic’s real-world value is evident in its widespread use across various sectors. From protective barriers in retail stores to illuminated signage on city streets, acrylic plays a vital role in enhancing safety, aesthetics, and functionality. Its versatility and durability make it an indispensable material for countless applications.

## Comprehensive & Trustworthy Review of Acrylic Sheets

Acrylic sheets offer a compelling combination of properties that make them a popular choice for a wide range of applications. However, it’s important to consider both the advantages and limitations to make an informed decision.

* **User Experience & Usability:** From a practical standpoint, acrylic sheets are relatively easy to work with. They can be cut, drilled, and shaped using standard tools, making them accessible to both professionals and DIY enthusiasts. The smooth surface and consistent thickness also contribute to ease of handling and installation. In our experience with acrylic sheets, we’ve found that proper preparation and the use of appropriate tools are key to achieving optimal results.

* **Performance & Effectiveness:** Acrylic sheets deliver on their promises of high clarity, weather resistance, and impact resistance. They provide excellent light transmission, maintain their appearance over time, and offer a degree of protection against shattering. Specific examples include acrylic windows that withstand harsh weather conditions and acrylic displays that maintain their clarity even after prolonged use.

* **Pros:**

1. **Exceptional Clarity:** Acrylic offers superior optical clarity compared to glass, providing a clearer view and brighter illumination.

2. **Weather Resistance:** Acrylic is highly resistant to UV radiation and moisture, making it suitable for outdoor applications.

3. **Impact Resistance:** Acrylic offers better impact resistance than glass, reducing the risk of shattering.

4. **Lightweight:** Acrylic is significantly lighter than glass, making it easier to handle and install.

5. **Ease of Fabrication:** Acrylic can be easily cut, drilled, and shaped using standard tools.

* **Cons/Limitations:**

1. **Scratch Resistance:** Acrylic is more prone to scratching than glass, requiring careful handling and cleaning.

2. **Chemical Sensitivity:** Acrylic can be damaged by strong solvents such as acetone.

3. **Cost:** Acrylic can be more expensive than some alternative materials.

4. **Flammability:** Acrylic is flammable and should not be used in applications where fire resistance is critical.

* **Ideal User Profile:** Acrylic sheets are best suited for applications where high clarity, weather resistance, and impact resistance are important considerations. They are a popular choice for signage, displays, windows, and protective barriers.

* **Key Alternatives (Briefly):** Polycarbonate offers higher impact resistance but is more expensive and less scratch-resistant. Glass offers superior scratch resistance but is heavier and more prone to shattering.

* **Expert Overall Verdict & Recommendation:** Based on our detailed analysis, acrylic sheets are a versatile and reliable material for a wide range of applications. While they have some limitations, the advantages generally outweigh the drawbacks. We recommend acrylic sheets for projects where clarity, weather resistance, and a degree of impact resistance are desired.

## Insightful Q&A Section

Here are 10 insightful questions and answers related to the *definition of acrylic* and its applications:

1. **Q: How does the manufacturing process (casting vs. extrusion) affect the properties of acrylic sheets?**

**A:** Cast acrylic generally offers superior optical clarity, scratch resistance, and chemical resistance compared to extruded acrylic. Extruded acrylic, on the other hand, is more cost-effective and may be more suitable for applications where these properties are not paramount.

2. **Q: What are some common mistakes to avoid when working with acrylic sheets?**

**A:** Common mistakes include using excessive heat when cutting or bending acrylic, which can cause it to crack or warp. Also, using the wrong type of adhesive can damage the surface. Proper ventilation is essential when working with acrylic adhesives.

3. **Q: How can I prevent acrylic sheets from scratching?**

**A:** Use a soft, lint-free cloth and a mild acrylic cleaner. Avoid using abrasive cleaners or scouring pads. Consider applying an anti-scratch coating to protect the surface.

4. **Q: What is the best way to clean acrylic sheets?**

**A:** Use a mild soap and water solution. Rinse thoroughly with clean water and dry with a soft cloth. Avoid using harsh chemicals or abrasive cleaners.

5. **Q: Can acrylic sheets be recycled?**

**A:** Yes, acrylic sheets can be recycled, but the process is not as widely available as recycling for other plastics. Check with your local recycling facilities for availability.

6. **Q: Are there different grades of acrylic sheets, and what are they used for?**

**A:** Yes, there are different grades of acrylic sheets, including general-purpose, UV-resistant, and impact-modified. UV-resistant acrylic is used for outdoor applications, while impact-modified acrylic is used for applications where high impact resistance is required.

7. **Q: How does acrylic compare to polycarbonate in terms of durability?**

**A:** Polycarbonate is generally more impact-resistant than acrylic, making it a better choice for applications where high impact resistance is critical. However, acrylic offers better optical clarity and scratch resistance.

8. **Q: What is the typical lifespan of acrylic sheets used outdoors?**

**A:** The lifespan of acrylic sheets used outdoors can vary depending on the climate and exposure to UV radiation. However, high-quality UV-resistant acrylic can last for 10 years or more with proper maintenance.

9. **Q: How does the thickness of an acrylic sheet affect its strength and flexibility?**

**A:** Thicker acrylic sheets are generally stronger and more rigid than thinner sheets. Thinner sheets are more flexible and can be bent or formed more easily.

10. **Q: What are some innovative applications of acrylic that are emerging in recent years?**

**A:** Recent innovative applications include acrylic used in 3D printing, advanced optical lenses, and in the creation of lightweight structural components in automotive and aerospace industries.

## Conclusion & Strategic Call to Action

In summary, the *definition of acrylic* encompasses a versatile family of thermoplastic polymers with a wide range of applications. Its unique combination of properties, including high clarity, weather resistance, and ease of fabrication, makes it an indispensable material for countless industries. We’ve explored its composition, manufacturing processes, advantages, and limitations, providing you with a comprehensive understanding of this important material. We hope this guide has been informative and helpful in answering your questions about acrylic.

As you continue to explore the possibilities of acrylic, we encourage you to share your experiences with definition of acrylic in the comments below. Explore our advanced guide to acrylic fabrication for more in-depth information on working with this versatile material. Contact our experts for a consultation on definition of acrylic and how it can benefit your specific applications. We are here to help you leverage the full potential of acrylic for your next project.