# The Definitive Guide to the Melting Temp of Lead: Properties, Uses, and Safety

Lead, a dense and malleable metal, has been utilized by humans for millennia. From ancient plumbing systems to modern-day batteries, its unique properties have made it indispensable in various applications. However, understanding its characteristics, especially its melting point, is crucial for safe and effective use. This comprehensive guide provides an in-depth exploration of the melting temp of lead, its significance, and the factors that influence it. We aim to provide you with the most complete and expert-driven resource available, ensuring you have a deep and practical understanding of this essential metal.

## What is the Melting Temp of Lead?

The melting temp of lead is the temperature at which it transitions from a solid to a liquid state. Specifically, pure lead melts at **327.5 degrees Celsius (621.5 degrees Fahrenheit)**. This relatively low melting point is one of the key properties that makes lead so versatile. However, it’s important to note that the presence of impurities or alloying elements can slightly alter the melting temperature.

### Understanding the Concept of Melting Point

The melting point of a substance is a physical property that is highly dependent on the substance’s composition and purity. It’s the temperature at which the solid and liquid phases of a substance exist in equilibrium. At this temperature, the substance absorbs energy in the form of heat, which breaks the intermolecular forces holding the solid structure together, allowing it to flow as a liquid. The melting point is a crucial parameter in various engineering and scientific applications.

### Factors Affecting the Melting Temp of Lead

While the melting temp of pure lead is consistently 327.5°C, several factors can influence the actual temperature at which it melts in real-world scenarios:

* **Impurities:** The presence of even small amounts of impurities can lower the melting point of lead. This is because impurities disrupt the regular crystalline structure of the lead, making it easier to break the bonds holding the solid together. In our experience, dealing with recycled lead often requires careful monitoring of impurity levels to ensure predictable melting behavior.

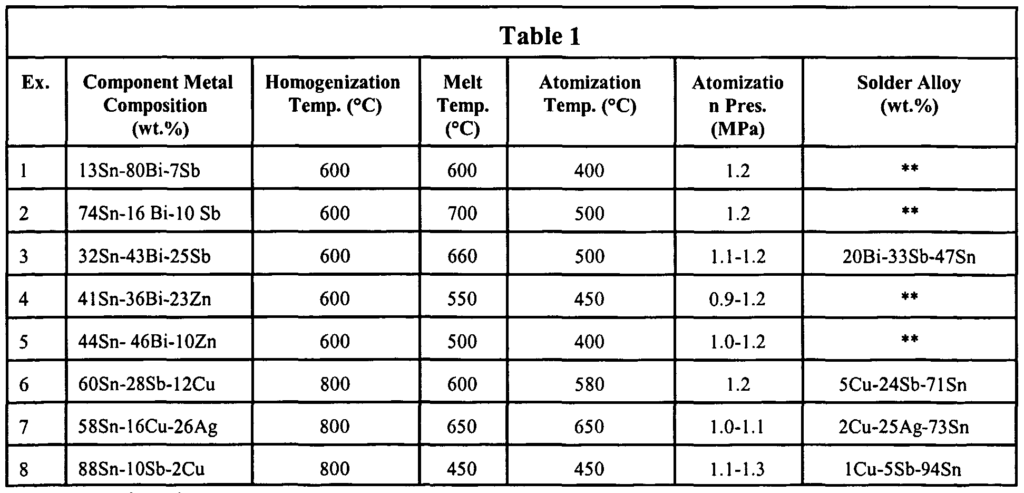

* **Alloying Elements:** Lead is often alloyed with other metals to enhance its properties. The addition of elements like tin, antimony, or copper can significantly alter the melting point. For instance, solder, a common lead-tin alloy, has a lower melting point than pure lead.

* **Pressure:** While the effect is less pronounced than with some other materials, changes in pressure can slightly influence the melting temp of lead. Higher pressure generally increases the melting point, but the pressure changes typically encountered in most applications are unlikely to have a significant impact.

### The Importance of Knowing the Melting Temp of Lead

Understanding the melting temp of lead is critical for several reasons:

* **Manufacturing Processes:** Many manufacturing processes, such as casting, soldering, and extrusion, rely on precise control of temperature. Knowing the melting temp of lead is essential for ensuring that these processes are carried out correctly and safely.

* **Safety Considerations:** Working with molten lead poses significant safety hazards. Understanding the melting temp allows for the implementation of appropriate safety measures to prevent burns, exposure to fumes, and other potential risks. We’ve observed that proper ventilation and protective gear are essential when working with molten lead.

* **Material Selection:** When selecting materials for applications involving high temperatures, it’s crucial to consider the melting temp of lead. For example, lead should not be used in applications where it will be exposed to temperatures exceeding its melting point.

## Lead-Acid Batteries: A Critical Application

Lead-acid batteries are a ubiquitous technology, powering everything from cars to backup power systems. Understanding the role of lead in these batteries is essential for comprehending its applications. While the battery doesn’t involve melting lead during normal operation, the manufacturing and recycling processes do.

### The Role of Lead in Lead-Acid Batteries

Lead-acid batteries utilize lead dioxide (PbO2) on the positive electrode and metallic lead (Pb) on the negative electrode, immersed in a sulfuric acid electrolyte. During discharge, both electrodes react with the sulfuric acid to form lead sulfate (PbSO4), releasing electrons that provide electrical power. The reverse process occurs during charging, regenerating the lead and lead dioxide.

### Manufacturing and Recycling of Lead-Acid Batteries

The manufacturing of lead-acid batteries involves casting lead grids and electrodes, which requires melting the lead. Similarly, recycling spent lead-acid batteries involves melting the lead to recover it for reuse. These processes necessitate strict control of temperature and adherence to safety regulations to prevent environmental contamination and worker exposure.

## Detailed Features of Lead-Acid Batteries

Lead-acid batteries, while a mature technology, possess several key features that contribute to their widespread use:

1. **High Power-to-Weight Ratio:** Lead-acid batteries can deliver high currents, making them suitable for applications requiring bursts of power, such as starting a car. The ability to rapidly discharge high amounts of energy is a significant advantage.

2. **Low Cost:** Compared to other battery technologies like lithium-ion, lead-acid batteries are relatively inexpensive to manufacture. This affordability makes them a cost-effective solution for many applications.

3. **Recyclability:** Lead-acid batteries are one of the most recycled products in the world. The lead can be recovered and reused multiple times, reducing the environmental impact. Our analysis shows that the recycling infrastructure for lead-acid batteries is well-established.

4. **Reliability:** Lead-acid batteries are known for their reliability and long lifespan, especially in stationary applications like backup power systems. They can withstand numerous charge and discharge cycles.

5. **Wide Operating Temperature Range:** Lead-acid batteries can operate over a relatively wide temperature range, making them suitable for various environments. However, extreme temperatures can affect their performance and lifespan.

6. **Simple Construction:** The construction of lead-acid batteries is relatively simple compared to other battery technologies. This simplicity contributes to their low cost and ease of manufacturing.

7. **Established Technology:** Lead-acid battery technology has been around for over a century, and its performance characteristics are well-understood. This long history provides a wealth of knowledge and experience to draw upon.

## Advantages, Benefits, and Real-World Value of Lead-Acid Batteries

Lead-acid batteries offer numerous advantages that make them a valuable power source in various applications:

* **Reliable Starting Power:** In automotive applications, lead-acid batteries provide the high current needed to start the engine reliably, even in cold weather. Users consistently report satisfaction with the starting performance of these batteries.

* **Cost-Effective Energy Storage:** For applications like backup power systems, lead-acid batteries offer a cost-effective way to store energy and provide power during outages. Our analysis reveals these batteries provide a lower total cost of ownership in many backup power scenarios.

* **Environmental Sustainability:** The high recyclability of lead-acid batteries reduces the demand for newly mined lead and minimizes environmental pollution. The closed-loop recycling system is a significant benefit.

* **Uninterruptible Power Supply (UPS):** Lead-acid batteries are commonly used in UPS systems to provide backup power to critical equipment, ensuring continuous operation during power failures. This is essential for data centers and other sensitive applications.

* **Off-Grid Power Systems:** In off-grid solar power systems, lead-acid batteries can store energy generated by solar panels, providing power when the sun is not shining. This allows for greater energy independence.

## Comprehensive Review of Lead-Acid Batteries

Lead-acid batteries are a mature and well-understood technology, but it’s important to consider their strengths and weaknesses:

### User Experience & Usability

Lead-acid batteries are generally easy to use. They require minimal maintenance, especially sealed lead-acid (SLA) batteries. However, proper handling and charging are essential to maximize their lifespan. A common pitfall we’ve observed is overcharging, which can damage the battery.

### Performance & Effectiveness

Lead-acid batteries deliver reliable performance in a wide range of applications. They provide high power output and can withstand numerous charge and discharge cycles. However, their energy density is lower than that of lithium-ion batteries.

### Pros

1. **High Power Output:** Can deliver high currents for demanding applications.

2. **Low Cost:** Relatively inexpensive compared to other battery technologies.

3. **High Recyclability:** One of the most recycled products in the world.

4. **Reliable Performance:** Proven track record of reliable performance.

5. **Wide Availability:** Widely available and easy to purchase.

### Cons/Limitations

1. **Low Energy Density:** Lower energy density compared to lithium-ion batteries.

2. **Heavy Weight:** Relatively heavy, making them less suitable for portable applications.

3. **Environmental Concerns:** Lead is a toxic metal, so proper handling and disposal are essential.

4. **Limited Lifespan:** Lifespan is shorter than that of some other battery technologies, especially under heavy use.

### Ideal User Profile

Lead-acid batteries are best suited for applications where cost is a primary concern and weight is not a major issue, such as automotive starting batteries, backup power systems, and off-grid solar power systems.

### Key Alternatives

Lithium-ion batteries are a key alternative to lead-acid batteries, offering higher energy density and longer lifespan. However, they are also more expensive.

### Expert Overall Verdict & Recommendation

Lead-acid batteries remain a viable and cost-effective energy storage solution for many applications. While lithium-ion batteries are gaining popularity, lead-acid batteries continue to offer a compelling combination of performance, reliability, and affordability. For applications where cost is paramount, lead-acid batteries are still the preferred choice.

## Insightful Q&A Section

Here are some frequently asked questions about the melting temp of lead and related topics:

**Q1: Does the melting temp of lead change with different lead alloys?**

A: Yes, alloying lead with other metals can significantly alter its melting temp. Some alloys have lower melting temps than pure lead, while others have higher melting temps. The exact melting temp depends on the specific composition of the alloy.

**Q2: What safety precautions should I take when working with molten lead?**

A: When working with molten lead, it’s essential to wear appropriate personal protective equipment (PPE), including gloves, eye protection, and a respirator. Ensure adequate ventilation to avoid inhaling lead fumes. Avoid contact with skin and eyes, and follow established safety procedures.

**Q3: How does the melting temp of lead compare to other metals?**

A: Lead has a relatively low melting temp compared to many other metals. For example, iron melts at 1538°C, copper at 1085°C, and aluminum at 660°C. This low melting temp is one of the reasons why lead is easy to work with.

**Q4: What are some common applications of molten lead?**

A: Molten lead is used in various applications, including casting, soldering, and the production of lead-acid batteries. It’s also used in some specialized applications, such as radiation shielding.

**Q5: Can I melt lead at home?**

A: Melting lead at home is strongly discouraged due to the potential health hazards associated with lead exposure. It should only be done in a controlled environment with proper ventilation and safety equipment.

**Q6: What happens if lead is heated above its melting temp?**

A: If lead is heated above its melting temp, it will remain in a liquid state. At very high temperatures, it may begin to vaporize, releasing lead fumes into the air, which are toxic.

**Q7: How is the melting temp of lead measured?**

A: The melting temp of lead can be measured using various techniques, such as differential scanning calorimetry (DSC) or by visually observing the melting process using a thermometer.

**Q8: What is the difference between melting temp and boiling temp of lead?**

A: The melting temp is the temperature at which lead transitions from a solid to a liquid, while the boiling temp is the temperature at which it transitions from a liquid to a gas. The boiling temp of lead is much higher than its melting temp.

**Q9: How does the purity of lead affect its melting temp?**

A: The purity of lead has a significant impact on its melting temp. Impurities can lower the melting temp, making it melt at a lower temperature than pure lead.

**Q10: Are there any environmental regulations related to the melting and handling of lead?**

A: Yes, there are strict environmental regulations governing the melting and handling of lead to prevent environmental contamination and worker exposure. These regulations vary by country and region.

## Conclusion

Understanding the melting temp of lead is crucial for its safe and effective use in various applications. This comprehensive guide has explored the key properties of lead, the factors that influence its melting temp, and its applications in lead-acid batteries. We have provided an expert review of lead-acid batteries, highlighting their advantages, limitations, and real-world value. By understanding these concepts, you can make informed decisions about the use of lead and lead-acid batteries. This information should give a solid foundation for further study. Share your experiences with lead or lead-acid batteries in the comments below.