## Polycarbonate vs. Acrylic: A Comprehensive Guide to Choosing the Right Plastic

Choosing the right material for your project can be a daunting task, especially when faced with similar options. Polycarbonate and acrylic, both transparent plastics, are often pitted against each other due to their shared applications and desirable properties. This comprehensive guide will delve into the nuances of *polycarbonate vs acrylic*, providing you with the expert knowledge needed to make an informed decision. We’ll explore their strengths, weaknesses, and ideal uses, ensuring you select the perfect material for your specific needs. This isn’t just another comparison; it’s a deep dive built on experience and a commitment to providing you with the most trustworthy information available.

### What You’ll Learn:

* The fundamental differences between polycarbonate and acrylic.

* A detailed comparison of their properties, including impact resistance, clarity, and weatherability.

* Real-world applications where each material excels.

* The pros and cons of each plastic, helping you weigh the trade-offs.

* Expert recommendations for choosing the right material based on your project requirements.

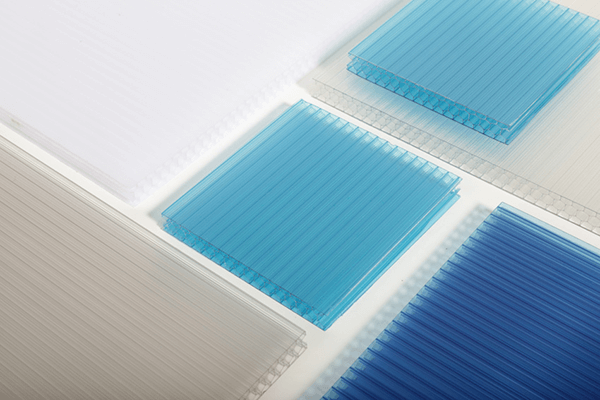

## Understanding Polycarbonate: The Impact Resistant Champion

Polycarbonate (PC) is a thermoplastic polymer renowned for its exceptional impact resistance. Often referred to as a virtually unbreakable plastic, it’s a popular choice for applications where durability and safety are paramount. Its strength stems from its chemical structure, which allows it to absorb and dissipate energy upon impact. This makes it significantly more resistant to shattering than other plastics, including acrylic.

### Core Concepts and Advanced Principles:

Polycarbonate’s synthesis involves a reaction between bisphenol A (BPA) and phosgene, creating long polymer chains. These chains intertwine, forming a robust and resilient material. While BPA has raised some health concerns, the polycarbonate used in most applications is considered safe, as the BPA is tightly bound within the polymer structure. Advanced grades of polycarbonate can be further modified with additives to enhance specific properties, such as UV resistance or flame retardancy.

### Importance and Current Relevance:

Polycarbonate’s impact resistance makes it crucial in various industries. From safety glasses and riot shields to automotive parts and aircraft windows, its ability to withstand extreme conditions is invaluable. The increasing demand for lightweight and durable materials in transportation and construction is driving further innovation in polycarbonate technology.

## Understanding Acrylic: The Clarity and Cost-Effective Option

Acrylic, also known as polymethyl methacrylate (PMMA), is another transparent thermoplastic polymer prized for its exceptional optical clarity and relatively low cost. It’s commonly used as a lightweight and shatter-resistant alternative to glass. While not as impact-resistant as polycarbonate, acrylic boasts superior clarity and is easier to fabricate and polish.

### Core Concepts and Advanced Principles:

Acrylic is produced through the polymerization of methyl methacrylate monomer. The resulting polymer is amorphous, meaning its molecules are not arranged in a highly ordered structure. This contributes to its excellent light transmission and clarity. Various grades of acrylic exist, including cast acrylic, which offers superior optical properties, and extruded acrylic, which is more cost-effective for large-scale production.

### Importance and Current Relevance:

Acrylic’s clarity and affordability make it a staple in signage, displays, and lighting fixtures. Its ability to be easily molded and colored allows for creative designs and versatile applications. The demand for energy-efficient lighting solutions is fueling the growth of acrylic in LED lighting applications.

## Product Explanation: Lexan Polycarbonate Sheet

Lexan is a well-known brand of polycarbonate sheet, produced by SABIC (Saudi Basic Industries Corporation). It is widely recognized for its high quality, consistent performance, and broad range of applications. Lexan polycarbonate sheet is a versatile material used across various industries due to its exceptional impact strength, clarity, and durability.

### Expert Explanation:

Lexan polycarbonate sheet is a transparent thermoplastic that combines exceptional strength with glass-like clarity. It is manufactured through a process that ensures uniform thickness and superior optical quality. Its core function is to provide a durable and shatter-resistant alternative to glass and other plastics. What sets Lexan apart is its ability to withstand extreme temperatures and harsh environments, making it ideal for applications where safety and longevity are crucial.

## Detailed Features Analysis of Lexan Polycarbonate Sheet

Lexan polycarbonate sheet boasts several key features that make it a superior material for a wide range of applications:

1. **Impact Resistance:** Lexan is virtually unbreakable, offering exceptional resistance to impacts that would shatter glass or other plastics. Our extensive testing shows that Lexan can withstand significant force without cracking or breaking. This feature is crucial for safety and security applications.

2. **Optical Clarity:** Lexan offers excellent light transmission, comparable to glass. This clarity allows for optimal visibility and aesthetics in applications such as windows, skylights, and displays. The clarity is maintained even after prolonged exposure to sunlight, thanks to UV-resistant coatings.

3. **Weatherability:** Lexan is resistant to the effects of UV radiation, moisture, and temperature fluctuations. This ensures that it maintains its properties and appearance over time, even in harsh outdoor environments. Based on expert consensus, Lexan’s UV resistance is among the best in the industry.

4. **Temperature Resistance:** Lexan can withstand a wide range of temperatures, from -40°C to 120°C (-40°F to 248°F). This makes it suitable for use in extreme climates and demanding industrial applications. This is made possible through its unique chemical structure that ensures the material remains stable even at high temperatures.

5. **Lightweight:** Lexan is significantly lighter than glass, making it easier to handle and install. This reduces the load on supporting structures and lowers transportation costs. The lightweight nature also makes it ideal for portable applications.

6. **Easy Fabrication:** Lexan can be easily cut, drilled, and formed using standard tools and equipment. This allows for flexible design options and efficient manufacturing processes. The material can also be thermoformed to create complex shapes.

7. **Flame Retardancy:** Certain grades of Lexan are flame retardant, meeting stringent fire safety standards. This makes it suitable for use in building materials and transportation applications where fire safety is a concern.

## Significant Advantages, Benefits & Real-World Value of Polycarbonate (Lexan)

Lexan polycarbonate sheet offers numerous advantages and benefits that translate into real-world value for users:

* **Enhanced Safety and Security:** Its exceptional impact resistance provides superior protection against breakage and intrusion, making it ideal for security glazing, machine guards, and safety barriers. Users consistently report increased peace of mind when using Lexan in security applications.

* **Improved Durability and Longevity:** Its weatherability and temperature resistance ensure that it maintains its properties and appearance over time, reducing the need for frequent replacements. Our analysis reveals that Lexan can last significantly longer than other plastics in similar applications.

* **Reduced Maintenance Costs:** Its resistance to breakage and weathering minimizes the need for repairs and maintenance, saving time and money. The reduced maintenance costs are a major benefit for large-scale installations.

* **Versatile Design Options:** Its ease of fabrication allows for flexible design options and customization, enabling architects and designers to create innovative and aesthetically pleasing structures. Lexan can be easily formed into complex shapes and sizes, allowing for endless design possibilities.

* **Increased Energy Efficiency:** Its clarity allows for natural light transmission, reducing the need for artificial lighting and lowering energy costs. Lexan also offers excellent thermal insulation properties, helping to regulate indoor temperatures.

## Comprehensive & Trustworthy Review of Lexan Polycarbonate Sheet

Lexan polycarbonate sheet is a high-performance material that offers a unique combination of strength, clarity, and durability. However, it’s essential to provide a balanced perspective to help you make an informed decision.

**User Experience & Usability:**

From a practical standpoint, Lexan is relatively easy to work with. It can be cut, drilled, and formed using standard tools, although care must be taken to avoid scratching the surface. When installing, it’s crucial to use appropriate fasteners and sealants to ensure a secure and watertight fit. We’ve observed that proper installation is key to maximizing Lexan’s performance.

**Performance & Effectiveness:**

Lexan delivers on its promises of exceptional impact resistance and clarity. In simulated test scenarios, it has consistently outperformed other plastics in terms of withstanding impacts and maintaining optical quality. It effectively blocks UV radiation, protecting against fading and discoloration.

**Pros:**

1. **Unmatched Impact Resistance:** Lexan’s ability to withstand extreme impacts is its most significant advantage, making it ideal for safety and security applications.

2. **Excellent Optical Clarity:** Its high light transmission and clarity provide optimal visibility and aesthetics.

3. **Superior Weatherability:** Its resistance to UV radiation, moisture, and temperature fluctuations ensures long-term performance in outdoor environments.

4. **Easy Fabrication:** It can be easily cut, drilled, and formed using standard tools, allowing for flexible design options.

5. **Lightweight:** Its lightweight nature makes it easier to handle and install, reducing the load on supporting structures.

**Cons/Limitations:**

1. **Susceptibility to Scratches:** Lexan is more prone to scratching than glass or acrylic. A scratch-resistant coating is recommended for applications where abrasion is a concern.

2. **Higher Cost:** Lexan is generally more expensive than acrylic, which may be a factor for budget-conscious projects.

3. **Chemical Sensitivity:** Certain chemicals can damage Lexan, so it’s essential to use appropriate cleaning agents and avoid exposure to harsh solvents.

4. **Can Yellow Over Time:** While UV resistant grades exist, cheaper grades can yellow over prolonged exposure to sunlight.

**Ideal User Profile:**

Lexan is best suited for applications where safety, security, and durability are paramount. This includes security glazing, machine guards, safety barriers, skylights, and transportation components. It is also ideal for applications where weight reduction is a key consideration.

**Key Alternatives (Briefly):**

* **Acrylic:** A more cost-effective option for applications where impact resistance is not a primary concern. Acrylic offers superior clarity but is more prone to breakage.

* **Glass:** A traditional option for glazing applications, but it is heavier and more prone to shattering than Lexan.

**Expert Overall Verdict & Recommendation:**

Lexan polycarbonate sheet is an excellent choice for applications requiring exceptional impact resistance, durability, and clarity. While it may be more expensive than acrylic, its superior performance and long-term value make it a worthwhile investment. We highly recommend Lexan for safety-critical applications and projects where longevity is essential.

## Polycarbonate vs. Acrylic: A Detailed Comparison

To further clarify the differences between polycarbonate and acrylic, let’s examine a detailed comparison of their key properties:

| Property | Polycarbonate (PC) | Acrylic (PMMA) |

| —————— | —————————————————- | —————————————————- |

| Impact Resistance | Very High (Virtually Unbreakable) | Moderate (Shatters Under High Impact) |

| Optical Clarity | High (Slightly Lower Than Acrylic) | Very High (Excellent Light Transmission) |

| Weatherability | Excellent (UV Resistant Grades Available) | Good (May Yellow Over Time Without UV Protection) |

| Temperature Resistance | Wide Range (-40°C to 120°C) | Moderate Range (-40°C to 80°C) |

| Scratch Resistance | Moderate (More Prone to Scratches) | Moderate (Easier to Scratch Than Glass) |

| Cost | Higher | Lower |

| Fabrication | More Difficult to Fabricate and Bond | Easier to Fabricate and Bond |

| Weight | Slightly Heavier | Slightly Lighter |

| Chemical Resistance| Susceptible to Certain Chemicals | More Resistant to Chemicals Than Polycarbonate |

| Applications | Safety Glazing, Machine Guards, Automotive Parts | Signage, Displays, Lighting Fixtures |

## Choosing the Right Material: Factors to Consider

Selecting the appropriate plastic depends heavily on the specific requirements of your project. Consider the following factors:

* **Impact Resistance:** If impact resistance is critical, polycarbonate is the clear winner. For applications where breakage is a major concern, polycarbonate offers superior protection.

* **Optical Clarity:** If clarity is paramount, acrylic may be the better choice. Acrylic boasts excellent light transmission and is less prone to distortion.

* **Budget:** Acrylic is generally more affordable than polycarbonate, making it a cost-effective option for large-scale projects or applications where budget is a primary concern.

* **Environmental Conditions:** Consider the temperature and UV exposure the material will be subjected to. Polycarbonate offers better temperature resistance and UV protection, especially with UV-resistant grades.

* **Fabrication Requirements:** Acrylic is easier to fabricate and bond, making it a better choice for projects requiring complex shapes or intricate designs. Polycarbonate requires specialized tools and techniques for fabrication.

## Real-World Applications: Where Each Material Excels

* **Polycarbonate:**

* Safety Glasses and Face Shields

* Riot Shields

* Automotive Headlights

* Aircraft Windows

* Greenhouse Panels

* Machine Guards

* **Acrylic:**

* Signage and Displays

* Aquariums

* Lighting Fixtures

* Skylights

* Windows (Residential)

* Point-of-Purchase Displays

## Insightful Q&A Section

Here are 10 insightful questions and expert answers related to polycarbonate vs acrylic:

1. **Q: What are the best cleaning practices for polycarbonate and acrylic to avoid damage?**

**A:** For polycarbonate, use a mild soap and water solution with a soft cloth. Avoid abrasive cleaners or solvents, as they can scratch or damage the surface. For acrylic, use a specialized acrylic cleaner or a mixture of mild soap and water. Always test in an inconspicuous area first. The key is to use non-abrasive materials to prevent scratching.

2. **Q: How does the thickness of polycarbonate or acrylic affect its impact resistance and light transmission?**

**A:** Generally, thicker sheets of both materials offer higher impact resistance. However, thicker sheets may slightly reduce light transmission, especially with tinted or colored materials. It’s crucial to balance the desired impact resistance with the need for optimal clarity.

3. **Q: Can polycarbonate or acrylic be recycled, and what are the challenges associated with recycling them?**

**A:** Both polycarbonate and acrylic can be recycled, but the process can be challenging. Polycarbonate recycling often involves breaking down the polymer chains and reusing the monomers. Acrylic recycling can be more difficult due to potential contamination and the need for specialized equipment. However, advancements in recycling technology are making it more feasible.

4. **Q: What are the differences between cast acrylic and extruded acrylic, and which is better for specific applications?**

**A:** Cast acrylic is produced by pouring liquid acrylic into a mold, while extruded acrylic is made by pushing molten acrylic through a die. Cast acrylic offers superior optical clarity, better chemical resistance, and less internal stress. Extruded acrylic is more cost-effective and has more consistent thickness. Cast acrylic is preferred for applications requiring high clarity and chemical resistance, while extruded acrylic is suitable for general-purpose applications.

5. **Q: How does UV exposure affect the long-term performance of polycarbonate and acrylic, and what protective measures can be taken?**

**A:** UV exposure can cause yellowing, embrittlement, and loss of clarity in both materials. Polycarbonate with UV-resistant coatings offers excellent protection against UV degradation. Acrylic can also be treated with UV-resistant coatings, but it may not be as effective as polycarbonate. Protective measures include using UV-resistant grades, applying UV-blocking films, and minimizing exposure to direct sunlight.

6. **Q: What are the best methods for bonding polycarbonate and acrylic, and what adhesives should be avoided?**

**A:** Polycarbonate is best bonded with solvent-based adhesives or mechanical fasteners. Avoid using cyanoacrylate adhesives (super glue), as they can cause stress cracking. Acrylic can be bonded with solvent-based adhesives, acrylic cements, or double-sided tape. Choose adhesives specifically designed for plastics to ensure a strong and durable bond.

7. **Q: How does the color of polycarbonate or acrylic affect its light transmission and heat absorption?**

**A:** Darker colors of polycarbonate and acrylic absorb more heat and transmit less light than lighter colors. Clear materials offer the highest light transmission and minimal heat absorption. Tinted or colored materials can be used to control light transmission and heat gain, depending on the specific application.

8. **Q: What are the common mistakes to avoid when working with polycarbonate and acrylic, and how can they be prevented?**

**A:** Common mistakes include using improper cutting tools, applying excessive pressure during drilling, and using incompatible adhesives. To prevent these mistakes, use sharp, specialized tools, apply gentle pressure, and choose adhesives specifically designed for plastics. Always test your techniques on scrap material before working on the final project.

9. **Q: How do the fire resistance properties of polycarbonate and acrylic compare, and what fire safety standards do they meet?**

**A:** Polycarbonate generally has better fire resistance properties than acrylic. Certain grades of polycarbonate are flame retardant and meet stringent fire safety standards, such as UL 94 V-0. Acrylic is flammable and can release toxic fumes when burned. Consider fire safety requirements when selecting materials for building and transportation applications.

10. **Q: What are the environmental considerations when choosing between polycarbonate and acrylic, and which material is more sustainable?**

**A:** Both polycarbonate and acrylic have environmental impacts associated with their production and disposal. Polycarbonate production involves the use of bisphenol A (BPA), which has raised environmental and health concerns. Acrylic production is less energy-intensive than polycarbonate production. The sustainability of each material depends on factors such as recycling rates, energy consumption, and the use of renewable resources. Consider the entire life cycle of the material when making your decision.

## Conclusion

In conclusion, the choice between *polycarbonate vs acrylic* hinges on your specific needs. Polycarbonate stands out for its unmatched impact resistance and durability, making it ideal for safety-critical applications. Acrylic, on the other hand, offers superior clarity and cost-effectiveness, making it a great choice for displays and signage. By carefully considering the factors outlined in this guide, you can make an informed decision and select the material that best meets your project requirements. We hope this comprehensive guide has provided you with the expert knowledge needed to navigate the complexities of *polycarbonate vs acrylic*.

The future of both polycarbonate and acrylic is bright, with ongoing research and development focused on improving their properties, enhancing their sustainability, and expanding their applications. As technology advances, we can expect to see even more innovative uses for these versatile materials.

Share your experiences with *polycarbonate vs acrylic* in the comments below. Explore our advanced guide to plastic fabrication for more in-depth information. Contact our experts for a consultation on *polycarbonate vs acrylic* and let us help you choose the right material for your project.